OTHER

Quality Control in Electronics Manufacturing: Best Practices and Strategies

Electronic devices have become an important component of every organization and industry.

Electronic manufacturing companies can make electronic devices with different methods but maintaining the quality of the device is another thing.

He should have to make sure that he uses the best methods to maintain the quality of the final product. However, to check the quality of the device there is a system called QMS (quality management system) which is based on international standards i.e. ISO 9001, ISO 13485, and TS16949. It gives the manufacturer all the instructions to control the quality during the process of electronics manufacturing or after the final product is made.

It has different features that can be used to detect errors in electronic manufacturing services or to check defaults in the final electronic device. The QMS system also has the quality policy which gives all the important information about quality control. Moreover, it also has the instructions to guide the manufacturers during the whole electronic manufacturing services.

In this article, you will find all the necessary information that could be helpful in maintaining the quality of any electronic device. It will provide you with different strategies and steps to ensure the quality of the final electronic device. The following are the different practices and strategies that you can consider for the better quality of electronic devices.

Hiring Quality Control Experts

If you want to make sure that you produce high-quality electronic devices, you should hire a person who is great at his job. This will reduce the cost of removing the errors and the time will also be saved. Because engineers play a vital role in electronics manufacturing or other electronic manufacturing services, if you hire someone who doesn’t know what he is doing then he will cause many troubles during the electronic manufacturing services and you will not be able to provide better quality to your potential customers. Before hiring someone you can check their expertise on different companies where they are doing the PCB quality control or other electronic devices. Hiring professionals is the first important step to ensure the quality of the PCBs.

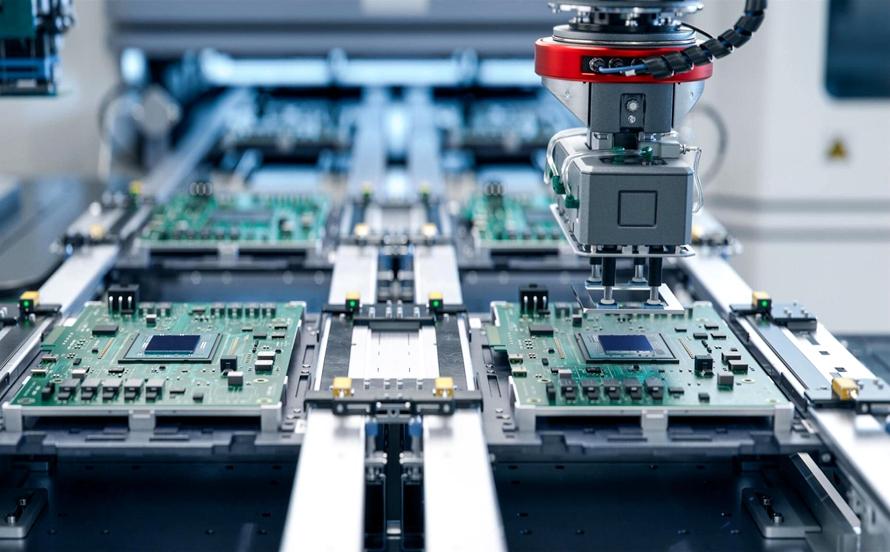

Automated Optical Inspection

Besides visual inspection, the electronics manufacturing companies can turn to visual inspection which can be done by the automated optical inspection machine. It equips a machine scanner that uses light imaging. An AOI machine typically contains many light sources and multiple cameras, sometimes including video cameras. The cameras on it can make 2D or 3D images of the devices which are of high-resolution. Therefore, it is a more reliable process than manual inspection. Because there are fewer chances of human errors as the entire process is automated. It can detect any errors in the soldering of PCB assembly. Therefore, to ensure the quality of PCB boards you should subject it to the automated optical inspection. It is also being used to test the PCBs that are produced in high volume to save time and cost.

X-Ray Inspection

Automated X-ray inspection is another strategy to check defects in PCB assembly and to make sure the quality of the PCB is not compromised. X-rays are used to examine internal features and subsurface conditions in test objects. X-ray inspection can find hidden features within a target object. It can make 2D or 3D images of the soldering paste on the PCB board. With the help of this, engineers can look for any unwanted space in the solder paste. The spectrum of use is broad and ranges from quality controls for electronics manufacturing, to the testing of materials for cracks and air inclusions, to foreign matter inclusions and shape deviations. This technique is mostly used to detect errors in small volume or prototypes. It can help you to reduce the cost of repairing the devices and it is the efficient technique that helps in maintaining the quality of the PCB board.

Functional Test

To make sure the electronic devices will work as the intention of the designer, it is better to do a functional test. It will simulate the usage situation and test if all the parameters are the same as the design. We usually need to produce functional testing fixtures first. But we should understand that it is difficult to test all the functions, but only test the main functions.

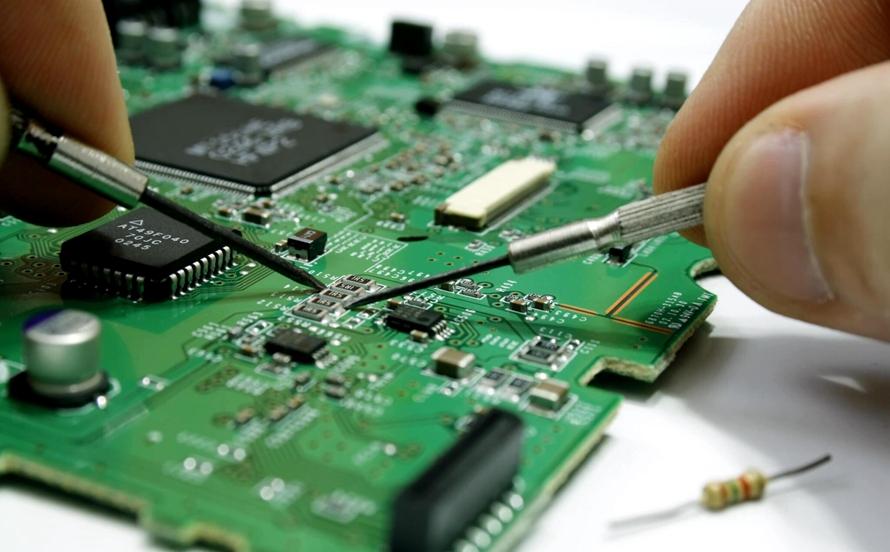

Visual Inspection

To find any errors in the PCB assembly, a visual inspection is done. The engineer may use a magnifier or he may try to find the fault in the soldering with his naked eyes. However, visual inspection is highly dependent on the skill of the worker. If he is an expert he may be able to find any errors in the assembly process. On the other hand, if the engineer is not an expert you will not be able to produce high-quality electronic devices. However, visual inspection turns out to be very effective, because it is not costly and can be done easily in electronics manufacturing.

Burn-In Testing

Burn-in testing is another technique to ensure quality control in PCB manufacturing. It is a type of stress test that involves applying extreme conditions to components or boards to eliminate failures. It can check the performance of the device in different environmental conditions. PCB boards are subjected to different temperatures, and currents to make sure that it will not burn out and will work properly once it is ready to sell. It can also be used to check the failures that may trigger in the future as well. Hence, it plays an important factor in ensuring the quality of electronic components and parts. Burn-in testing comprises two different types of tests:

-

Static Testing

-

Dynamic Testing

To Sum Up

To make sure that you are providing your customers with the best quality, an electronic manufacturing company should follow the best practices and strategies that would help you to make high-quality products and reduce the errors in electronics manufacturing. An electronic manufacturing company should have the best quality control department in your organization because it will help you to reduce human errors and poor-quality products.

OTHER

Why Malia Obama Received Major Criticism Over A Secret Facebook Page Dissing Trump

Given the divisive nature of both the Obama and Trump administrations, it’s unsurprising that reactions to Malia Obama’s alleged secret Facebook account would be emotional. Many online users were quick to jump to former President Donald Trump’s defense, with one user writing: “Dear Malia: Do you really think that anyone cares whether you and/or your family likes your father’s successor? We’re all trying to forget you and your family.”

Others pointed out the double standard held by those who condemn Trump for hateful rhetoric but praise people like Malia who speak out against her father’s successor in what they believe to be hateful rhetoric. Some users seemed bent on criticizing Malia simply because they don’t like her or her father, proving that the eldest Obama daughter couldn’t win for losing regarding the public’s perception of her or her online presence.

The secret Facebook situation is not all that dissimilar to critics who went after Malia for her professional name at the 2024 Sundance Film Festival. In this instance, people ironically accused Malia of using her family’s name to get into the competitive festival while also condemning her for opting not to use her surname, going by Malia Ann instead.

OTHER

Best Practices for Data Center Decommissioning and IT Asset Disposition

Data center decommissioning is a complicated process that requires careful planning and experienced professionals.

If you’re considering shutting down or moving your data center, here are some best practices to keep in mind:

Decommissioning a Data Center is More than Just Taking Down Physical Equipment

Decommissioning a data center is more than just taking down physical equipment. It involves properly disposing of data center assets, including servers and other IT assets that can contain sensitive information. The process also requires a team with the right skills and experience to ensure that all data has been properly wiped from storage media before they’re disposed of.

Data Centers Can be Decommissioned in Phases, Which Allows For More Flexibility

When you begin your data center decommissioning process, it’s important to understand that it’s not an event. Instead, it’s a process that takes place over time and in phases. This flexibility allows you to adapt as circumstances change and make adjustments based on your unique situation. For example:

-

You may start by shutting down parts of the facility (or all) while keeping others running until they are no longer needed or cost-effective to keep running.

-

When you’re ready for full shutdown, there could be some equipment still in use at other locations within the company (such as remote offices). These can be moved back into storage until needed again.

Data Center Decommissioning is Subject to Compliance Guidelines

Data center decommissioning is subject to compliance guidelines. Compliance guidelines may change, but they are always in place to ensure that your organization is following industry standards and best practices.

-

Local, state and federal regulations: You should check local ordinances regarding the disposal of any hazardous materials that were used in your data center (such as lead-based paint), as well as any other applicable laws related to environmental impact or safety issues. If you’re unsure about how these might affect your plans for a decommissioned facility, consult an attorney who specializes in this area of law before proceeding with any activities related to IT asset disposition or building demolition.

-

Industry standards: There are many industry associations dedicated specifically toward helping businesses stay compliant with legal requirements when moving forward with projects such as data center decommissioning.

-

Internal policies & procedures: Make sure everyone on staff understands how important it is not just from a regulatory standpoint but also from an ethical one; nobody wants their name associated with anything inappropriate!

Companies Should Consider Safety and Security During the Decommissioning Process

Data center decommissioning is a complex process that involves several steps. Companies need to consider the risks associated with each step of the process, and they should have a plan in place to mitigate these risks. The first step of data center decommissioning is identifying all assets and determining which ones will be reused or repurposed. At this point, you should also determine how long it will take for each asset to be repurposed or recycled so that you can estimate how much money it will cost for this part of your project (this can be done through an estimate based on previous experience).

The second step involves removing any hazardous materials from electronic equipment before it’s sent off site for recycling; this includes chemicals used in manufacturing processes like lead-free solder paste adhesives used on circuit boards made from tin-based alloys containing up 80% pure tin ingots stamped out into flat sheets called “pucks”. Once these chemicals have been removed from whatever device needs them taken off their surfaces then those devices can safely go through any other necessary processes such as grinding away excess plastic housing material using high pressure water jets until only its bare frame remains intact without any cracks where moisture might collect inside later causing corrosion damage over time due too much moisture exposure.

With Proper Planning and an Effective Team, You’ll Help Protect Your Company’s Future

Data center decommissioning is a complex process that should be handled by a team of experts with extensive experience in the field. With proper planning, you can ensure a smooth transition from your current data center environment to the next one.

The first step toward a successful data center decommissioning project is to create a plan for removing hardware and software assets from the building, as well as documenting how these assets were originally installed in the facility. This will allow you or another team member who may inherit some of these assets later on down the line to easily find out where they need to go when it’s time for them to be moved again (or disposed).

Use Professional Data Center Decommissioning Companies

In order to ensure that you get the most out of your data center decommissioning project, it’s important to use a professional data center decommissioning company. A professional data center decommissioning company has experience with IT asset disposition and can help you avoid mistakes in the process. They also have the tools and expertise needed to efficiently perform all aspects of your project, from pre-planning through finalizing documentation.

Proper Planning Will Help Minimize the Risks of Data Center Decommissioning

Proper planning is the key to success when it comes to the data center decommissioning process. It’s important that you don’t wait until the last minute and rush through this process, as it can lead to mistakes and wasted time. Proper planning will help minimize any risks associated with shutting down or moving a data center, keeping your company safe from harm and ensuring that all necessary steps are taken before shutdown takes place.

To Sum Up

The key to a successful ITAD program is planning ahead. The best way to avoid unexpected costs and delays is to plan your ITAD project carefully before you start. The best practices described in this article will help you understand what it takes to decommission an entire data center or other large facility, as well as how to dispose of their assets in an environmentally responsible manner.

OTHER

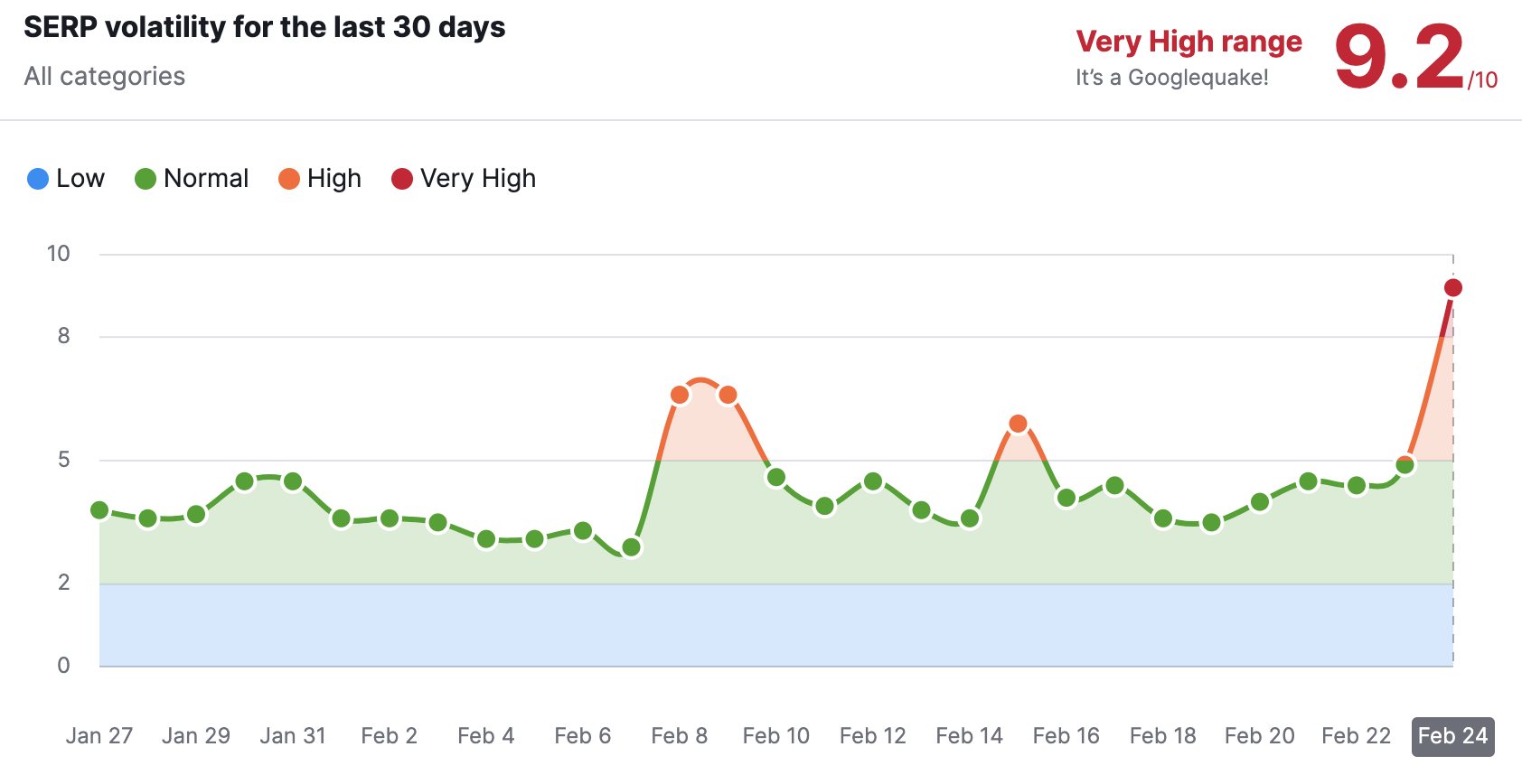

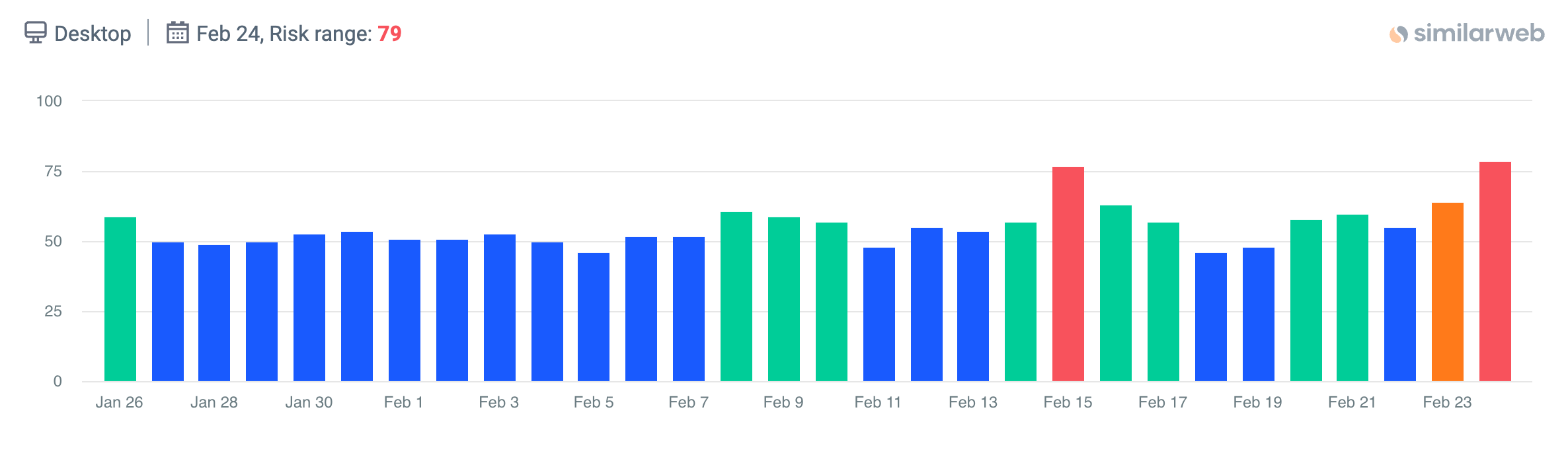

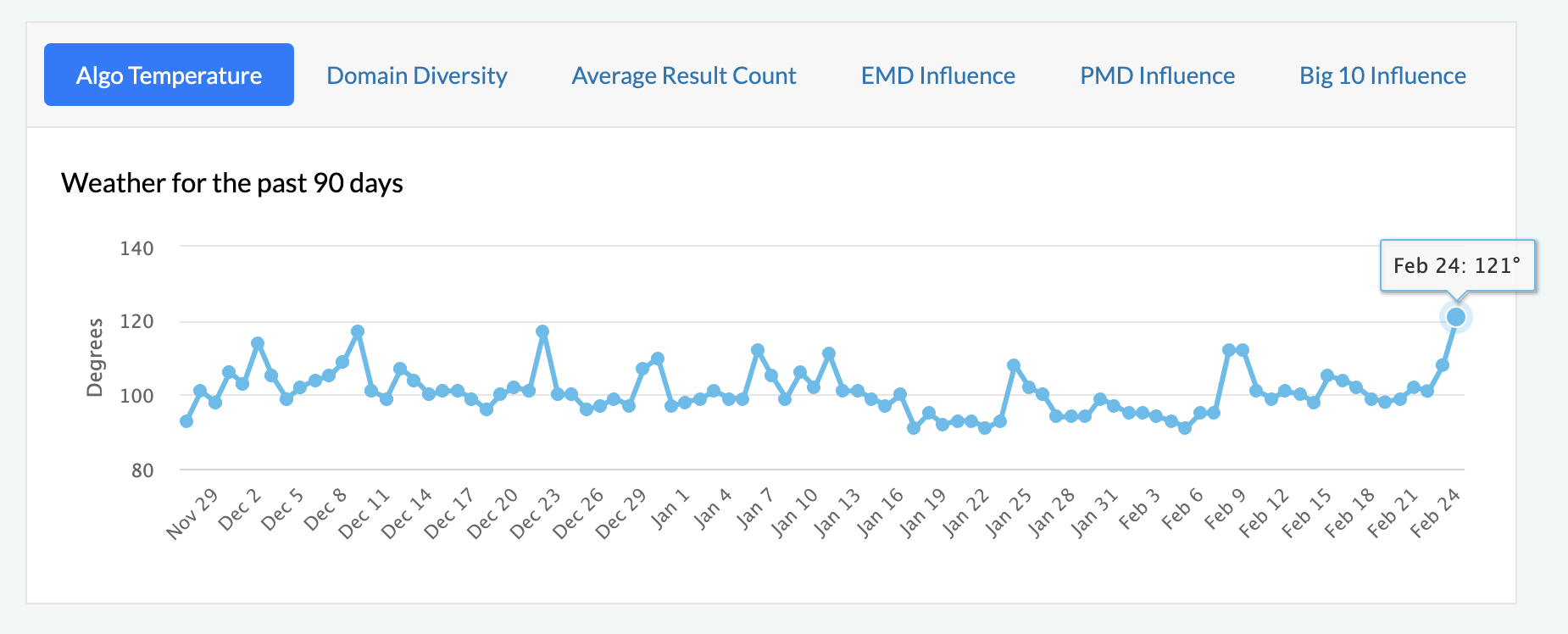

Massive Volatility Reported – Google Search Ranking Algorithm Update

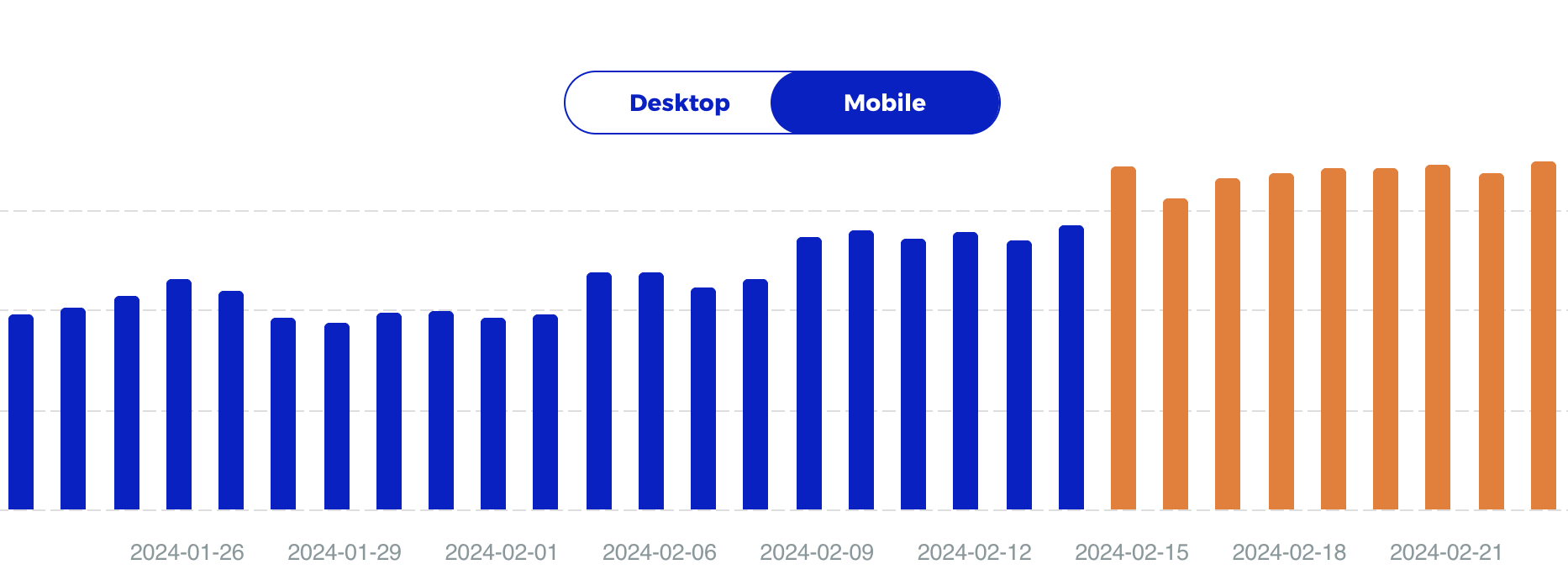

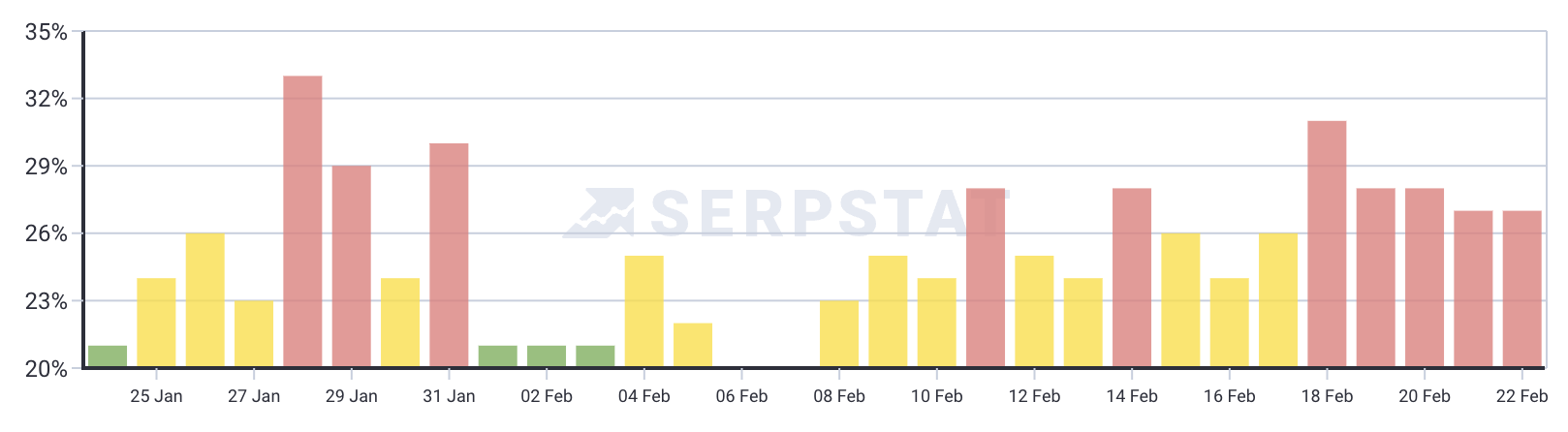

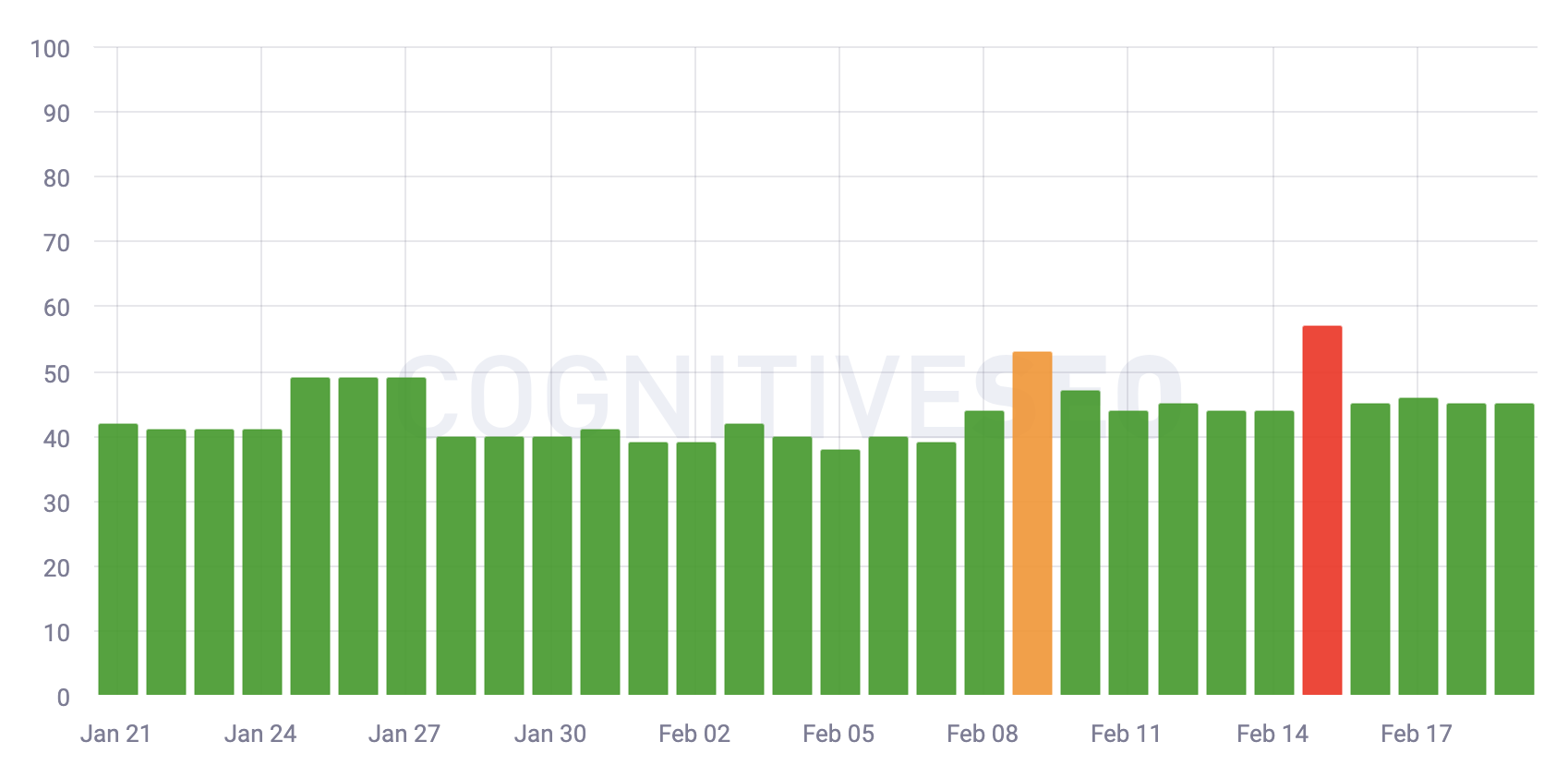

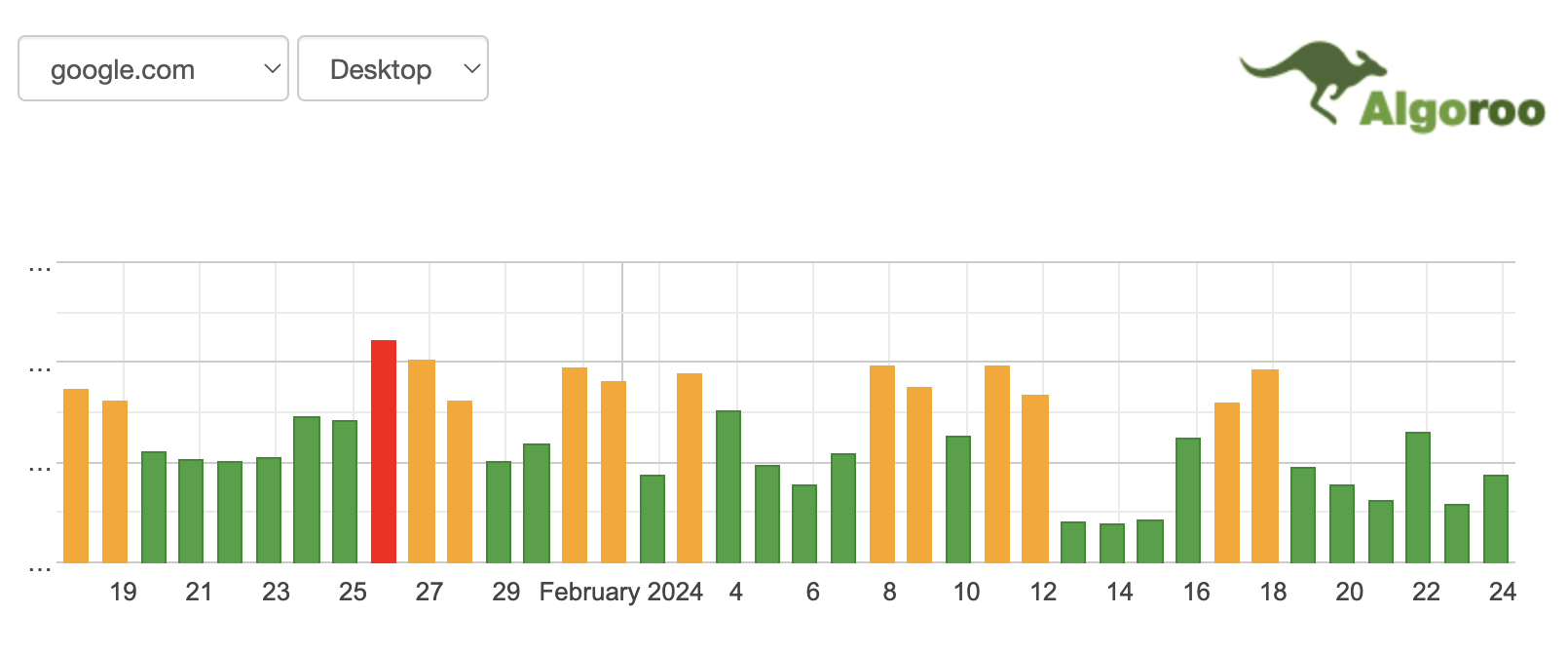

I am seeing some massive volatility being reported today after seeing a spike in chatter within the SEO community on Friday. I have not seen the third-party Google tracking tools show this much volatility in a long time. I will say the tracking tools are way more heated than the chatter I am seeing, so something might be off here.

Again, I saw some initial chatter from within the SEO forums and on this site starting on Friday. I decided not to cover it on Friday because the chatter was not at the levels that would warrant me posting something. Plus, while some of the tools started to show a lift in volatility, most of the tools did not yet.

To be clear, Google has not confirmed any update is officially going on.

Well, that changed today, and the tools are all superheated today.

Google Tracking Tools:

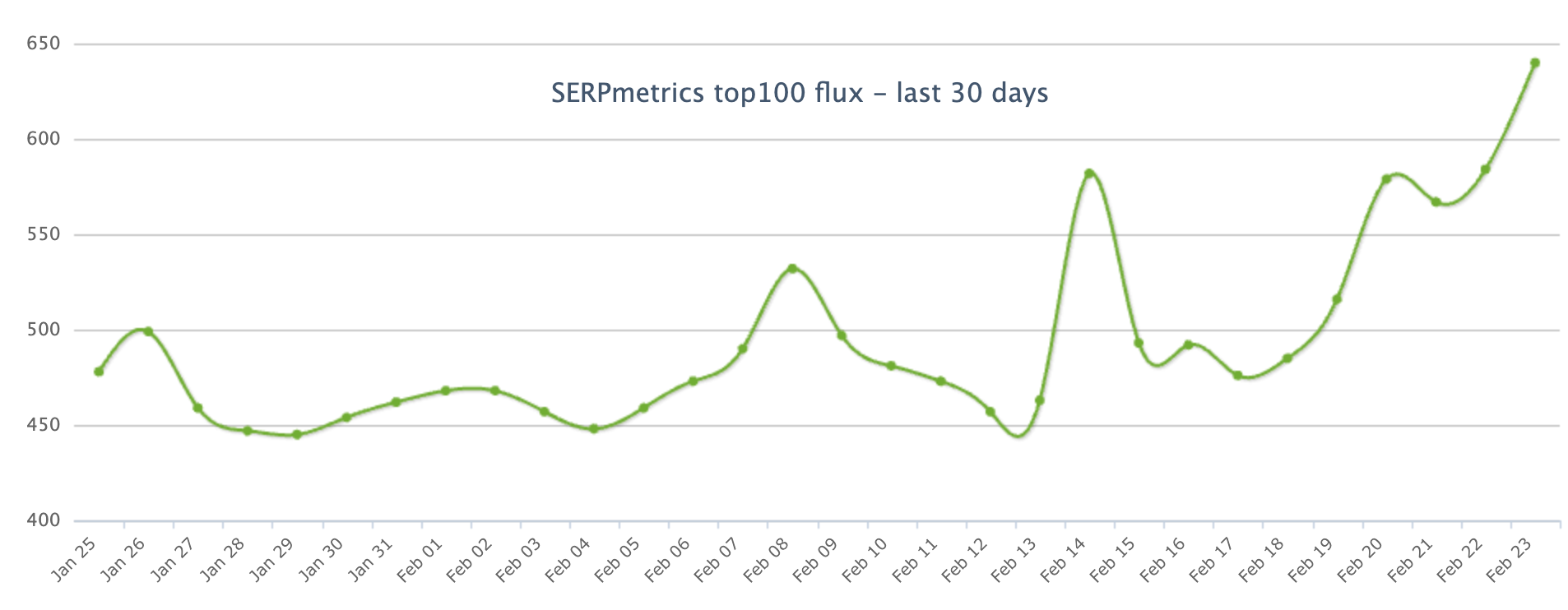

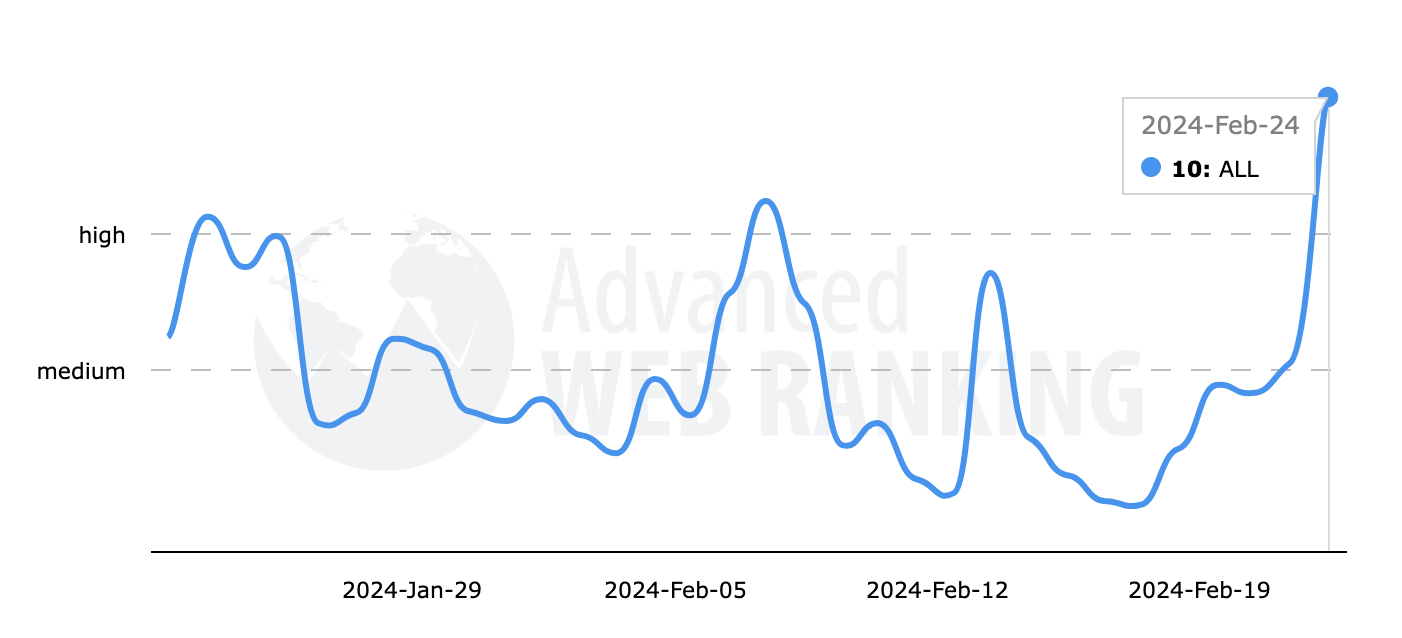

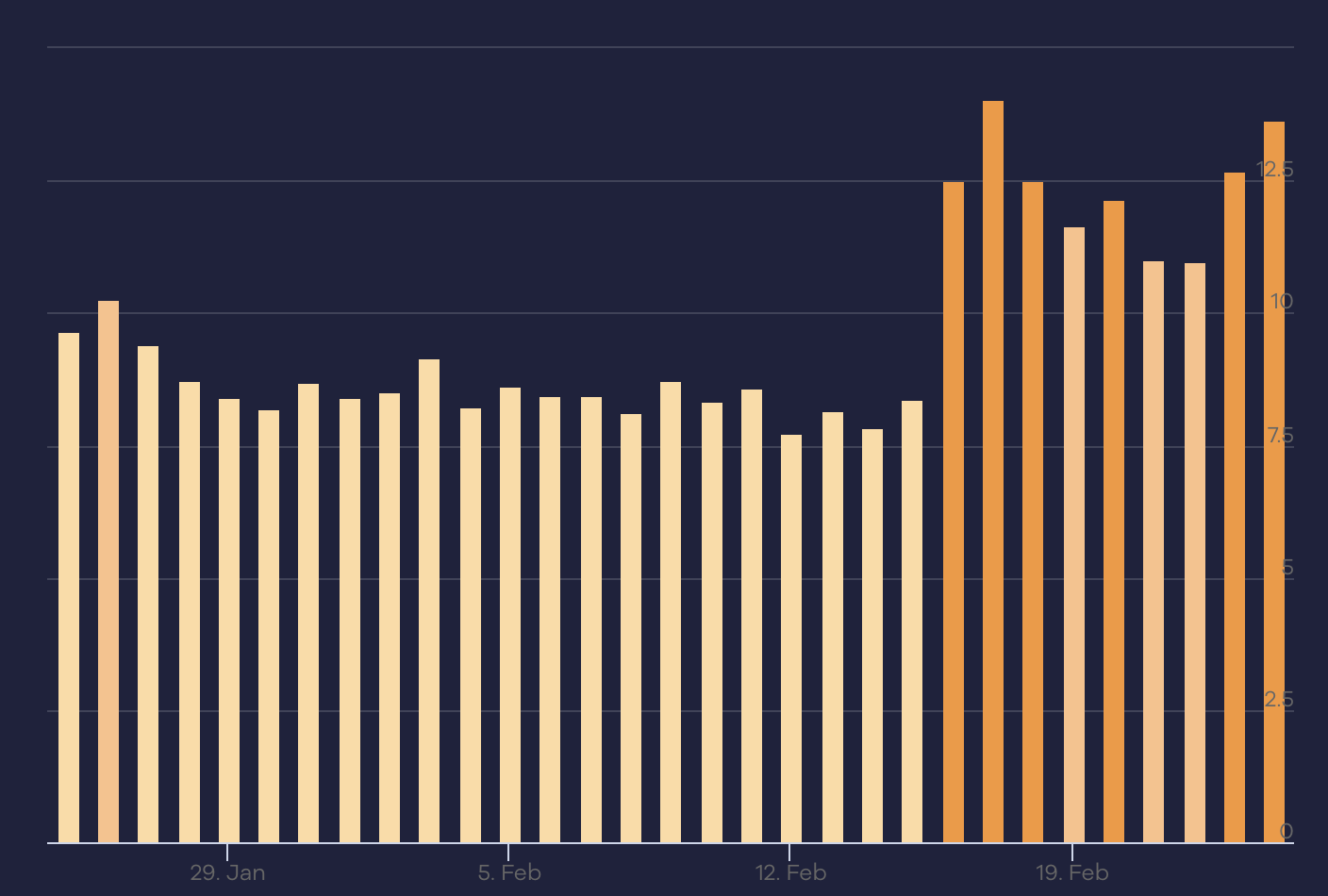

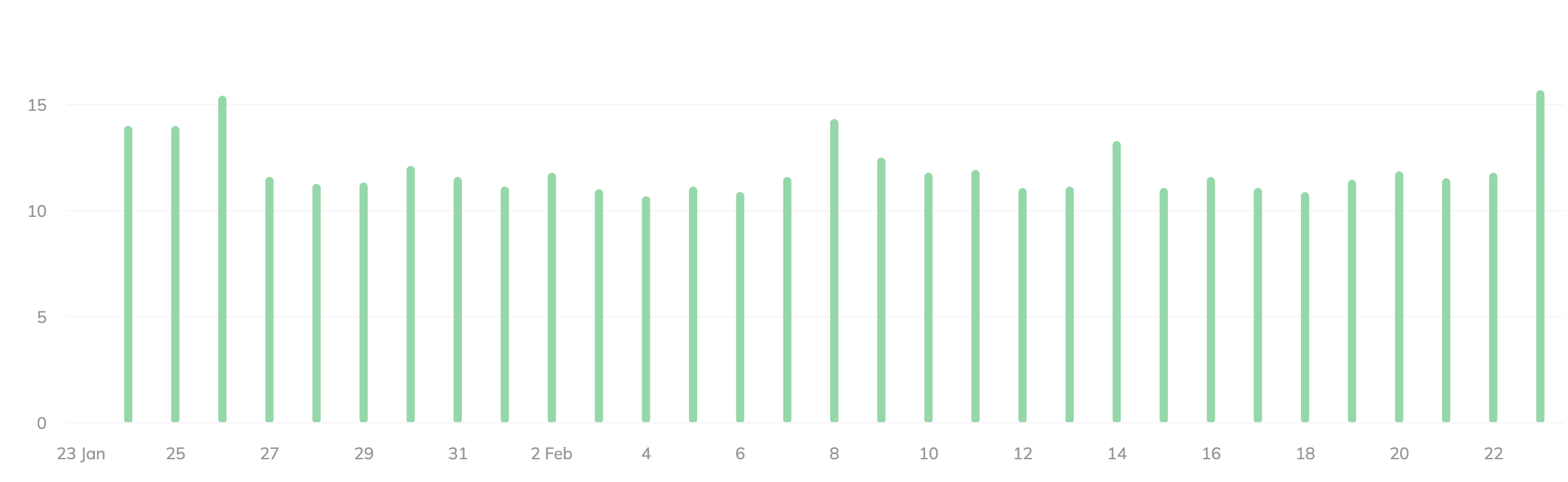

Let’s start with what the tools are showing:

So most of these tools are incredibly heated, signaling that they are showing massive changes in the search result positions in the past couple of days.

SEO Chatter

Here is some of the chatter from various comments on this site and on WebmasterWorld since Friday:

Speaking of, is anyone seeing some major shuffling going on in the SERPs today? It’s a Friday so of course Google is playing around again.

Something is going on.

Pages are still randomly dropping out of the index for 8-36h at a time. Extremely annoying.

Speaking of, is anyone seeing some major shuffling going on in the SERPs today? It’s a Friday so of course Google is playing around again

In SerpRobot I’m seeing a steady increase in positions in February, for UK desktop and mobile, reaching almost the ranks from the end of Sep 2023. Ahrefs shows a slight increase in overall keywords and ranks.

In the real world, nothing seems to happen.

yep, traffic has nearly come to a stop. But exactly the same situation happened to us last Friday as well.

USA traffic continues to be whacked…starting -70% today.

In my case, US traffic is almost zero (15 % from 80%) and the rest is kind of the same I guess. Traffic has dropped from 4K a day to barely scrapping 1K now. But a lot is just bots since payment-wise, the real traffic seems to be about 400-500. And … that’s how a 90% reduction looks like.

Something is happening now. Google algo is going crazy again. Is anyone else noticing?

Since every Saturday at 12 noon the Google traffic completely disappears until Sunday, everything looks normal to me.

This update looks like a weird one and no, Google has not confirmed any update is going on.

What are you all noticing?

Forum discussion at WebmasterWorld.

-

PPC6 days ago

PPC6 days ago19 Best SEO Tools in 2024 (For Every Use Case)

-

SEARCHENGINES5 days ago

Daily Search Forum Recap: April 19, 2024

-

MARKETING6 days ago

MARKETING6 days agoEcommerce evolution: Blurring the lines between B2B and B2C

-

SEARCHENGINES6 days ago

Daily Search Forum Recap: April 18, 2024

-

WORDPRESS5 days ago

WORDPRESS5 days agoHow to Make $5000 of Passive Income Every Month in WordPress

-

SEO6 days ago

SEO6 days ago2024 WordPress Vulnerability Report Shows Errors Sites Keep Making

-

WORDPRESS6 days ago

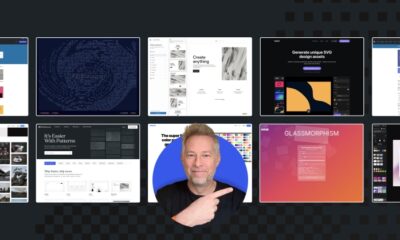

WORDPRESS6 days ago10 Amazing WordPress Design Resouces – WordPress.com News

-

WORDPRESS7 days ago

[GET] The7 Website And Ecommerce Builder For WordPress