TECHNOLOGY

Impact of Smart Robots in Industry 4.0

Smart robots in industry 4.0 help businesses achieve higher automation, flexibility and efficiency levels while improving safety and lowering the risk of errors and accidents.

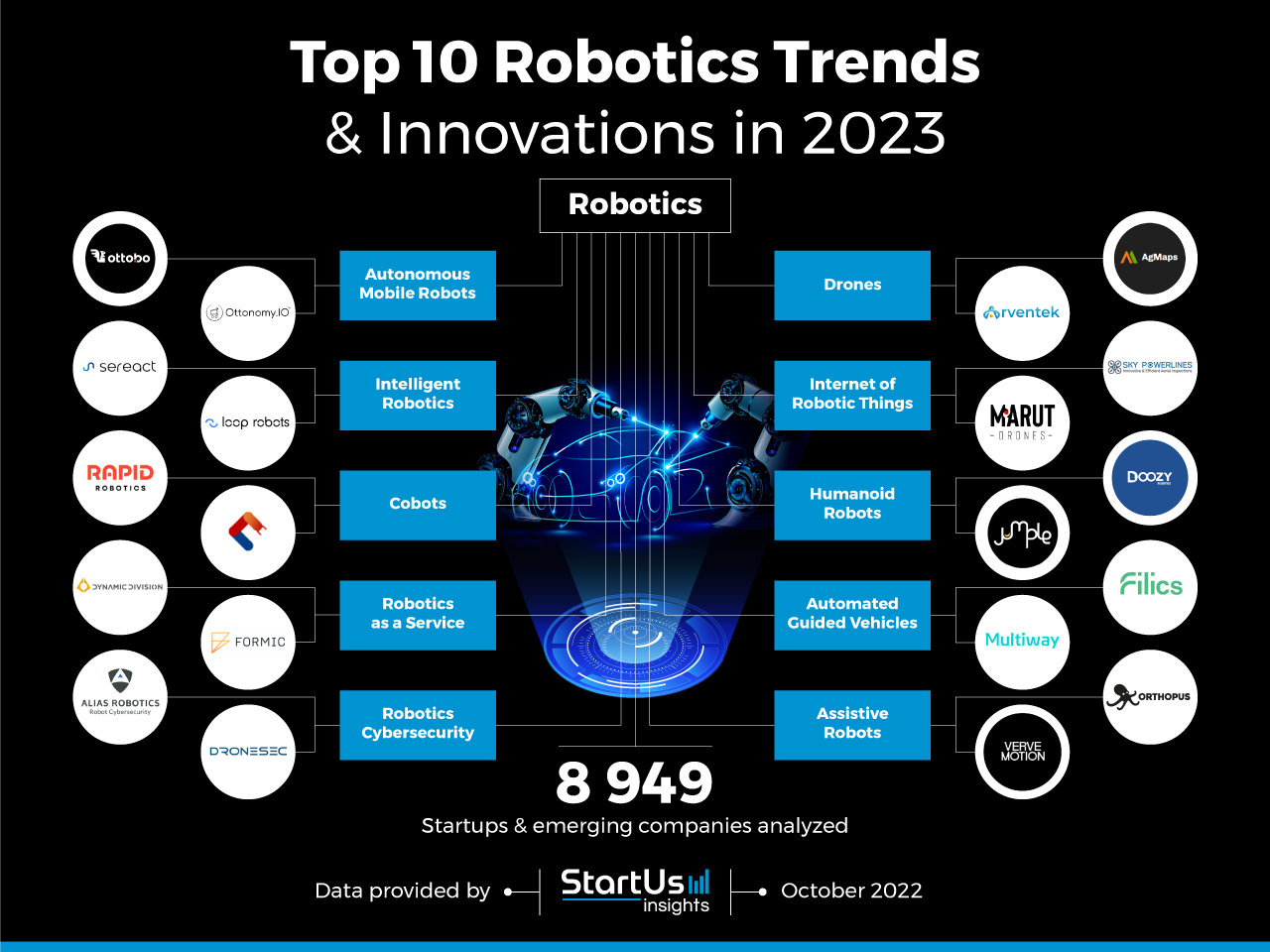

Since the 1800s, humanity has experienced three industrial revolutions, each marked by an innovative technology transforming manufacturing and processes. The steam engine, assembly line and computer propelled previous courses. We are now amid industry 4.0 – the current industrial revolution – powered by robotics, automation and the Internet of Things (IoT). The emergence of smart systems and digital integration has caused significant disruption in almost every industry worldwide. The manufacturing and industrial landscape is undergoing significant change today as we enter the fourth industrial revolution. The rise of smart robots in industry 4.0 is revolutionizing how we work and produce goods. Smart robots are designed to work alongside humans, performing repetitive, dangerous roles or tasks requiring a level of precision that humans cannot consistently achieve. They are embedded with advanced sensors, artificial intelligence and machine learning algorithms that allow them to learn, adapt and improve over time. The impact of smart robots in industry 4.0 is already felt in various sectors, from automotive and electronics to healthcare and logistics. They are revolutionizing how products are designed, manufactured and delivered, making the process faster, more efficient and less expensive.

Smart robots in industry 4.0 are enhancing various tasks to make organizational processes more efficient and effective by:

PROVIDING PREDICTIVE MAINTENANCE

Smart robots in industry 4.0 can provide predictive maintenance by detecting and analyzing data from equipment and machines using advanced sensors and machine learning algorithms. They can identify potential issues before they cause a breakdown or failure by monitoring performance data such as temperature, vibration and other indicators. Additionally, using predictive maintenance, smart robots in industry 4.0 can predict when equipment will require maintenance, repair or replacement and schedule maintenance activities in advance. This method can reduce downtime, boost productivity and extend machinery life, resulting in significant business cost savings.

ENHANCING PRODUCT QUALITY

Thanks to advanced sensors, machine learning algorithms and data analysis capabilities, smart robots in industry 4.0 can improve product quality in various ways. For starters, these robots can detect product flaws during manufacturing, allowing for rapid identification and correction of problems. They can also detect errors that human inspectors might miss using sensors to measure product dimensions, weight and appearance. This reduces the number of defective products reaching the market, improving overall product quality. Furthermore, intelligent robots can monitor production processes in real time, adjusting settings to improve quality and reduce defects. A smart robot, for example, may adjust the temperature, pressure or speed of a production line based on data collected from sensors, resulting in higher-quality products.

IMPROVING PRODUCTIVITY

Smart robots in industry 4.0 are programmed to perform repetitive or monotonous tasks, liberating manual workers to focus on more complex tasks. Automation can provide a significant advantage for large manufacturing operations by allowing tasks to be completed around the clock without incurring additional labor costs. Small businesses, which typically lack the resources to hire large workforces, could benefit significantly from effective task automation. Small businesses can compete on a more level playing field with larger manufacturing companies by using robots to handle specific tasks.

DECREASING OVERHEAD COSTS

Although automated software and robots have a high initial cost, they can provide quick returns on investment. By utilizing smart robots in industrial 4.0, business owners may discover that certain job positions are no longer required, resulting in immediate cost savings. Also, fewer employees would be exposed to hazardous working conditions so that businesses could save money on health and safety costs due to fewer injuries or absences. Many robots require little space and can work safely alongside humans on assembly lines. As a result of the reduced space requirement, businesses may be able to downsize to less expensive workplaces and factories.

ELIMINATING HUMAN ERROR

Smart robots in industry 4.0 can eliminate human error by taking over tasks prone to errors or inconsistencies, improving accuracy and lowering the risk of errors. They can perform precision and accuracy tasks like product assembly or quality control inspections. These robots are programmed to detect even minor deviations from standards and make corrections automatically, ensuring that every product is produced to the highest possible standard, thanks to advanced sensors and machine learning algorithms. Furthermore, smart robots can reduce the risk of human error in dangerous environments by performing hazardous or physically demanding tasks for humans. Robots, for instance, can handle tasks involving toxic chemicals or high temperatures, lowering the risk of accidents and injuries.

ALLOWING COLLABORATIVE WORK

Processing plants in traditional manufacturing facilities operate independently, reducing opportunities to share knowledge or collaborate with other plants. Smart robots in industry 4.0, on the other hand, enable employees to communicate and share information regardless of location or time zone. This means that knowledge gained from one machine or facility can be shared with other processing plants throughout the organization, increasing overall productivity. An advantage of industry 4.0 is the ability to share knowledge between systems or machines without human intervention automatically. For example, data collected from a machine in one location can improve production processes in other facilities worldwide. Businesses can use their entire organization’s knowledge to drive innovation and improve performance.

Industry 4.0 ushers in a new era of manufacturing and production, propelled by advanced technologies like robotics, automation and the Internet of Things. Smart robots in industry 4.0 are at the vanguard of this revolution, offering numerous advantages such as improved product quality, predictive maintenance and increased efficiency. They take on repetitive tasks, allowing human workers to focus on more complex duties while lowering human errors and refining accuracy. They also allow tasks to be completed around the clock, increasing output while incurring no additional labor costs. As the fourth industrial revolution gains traction, the role of smart robots will become even more important. Manufacturers can streamline operations, increase efficiency and stay ahead of the competition in an ever-changing global marketplace by leveraging the power of these advanced technologies.

![How AEO Will Impact Your Business's Google Visibility in 2026 Why Your Small Business’s Google Visibility in 2026 Depends on AEO [Webinar]](https://articles.entireweb.com/wp-content/uploads/2026/01/How-AEO-Will-Impact-Your-Businesss-Google-Visibility-in-2026-400x240.png)

![How AEO Will Impact Your Business's Google Visibility in 2026 Why Your Small Business’s Google Visibility in 2026 Depends on AEO [Webinar]](https://articles.entireweb.com/wp-content/uploads/2026/01/How-AEO-Will-Impact-Your-Businesss-Google-Visibility-in-2026-80x80.png)