TECHNOLOGY

Robotics is Revolutionizing the Mining Industry

The mining industry is one of the most important industries in the world, providing raw materials for a variety of products and industries.

However, mining operations can be dangerous and expensive, with many challenges such as underground mining and harsh environmental conditions. Robotics has the potential to revolutionize the mining industry, making it safer, more efficient, and more cost-effective. In this article, we will explore how robotics is being used in the mining industry through various examples including its benefits and challenges.

Benefits of Robotics in Mining

There are several benefits of robotics in mining operations:

-

Increased Safety: Robotics can reduce the risk of accidents and injuries in mining operations. Autonomous vehicles and robotic equipment can operate in hazardous environments, such as underground mines, reducing the risk of harm to human operators.

-

Improved Efficiency: Robotics can perform tasks more quickly and efficiently than human operators, improving productivity and reducing costs. Autonomous vehicles can operate 24/7, reducing the need for shift changes and increasing the amount of work that can be done in a given period.

-

Cost Reduction: Robotics can reduce labor costs by reducing the need for human operators. Additionally, autonomous vehicles can reduce fuel consumption and maintenance costs by optimizing routes and reducing unnecessary movement.

-

Environmental Benefits: Robotics can reduce the environmental impact of mining operations by reducing the amount of waste and emissions produced. Autonomous vehicles can optimize routes, reducing fuel consumption and emissions, while robotic equipment can perform tasks more accurately, reducing the amount of material wasted.

-

Increased Accuracy: Robotic equipment can perform tasks more accurately than human operators, improving the quality of mining operations. For example, robotic drilling equipment can drill holes more accurately and consistently than human operators, improving the efficiency of the drilling process.

Use Cases of Robotics in Mining

There are several use cases of robotics in mining, including:

Autonomous Mining Vehicles

Autonomous mining vehicles are one of the most significant applications of robotics in the mining industry. These vehicles can operate without a human driver, reducing the risk of accidents and increasing productivity. They can also operate in harsh environmental conditions, such as extreme temperatures and dust.

For example, Rio Tinto, one of the world’s largest mining companies, has been using autonomous mining trucks since 2008. These trucks can operate 24/7 and have significantly reduced the risk of accidents and increased productivity. Rio Tinto has also been developing autonomous drilling systems, which can operate in remote locations and drill holes more accurately and efficiently than human operators.

Robotic Mining Equipment

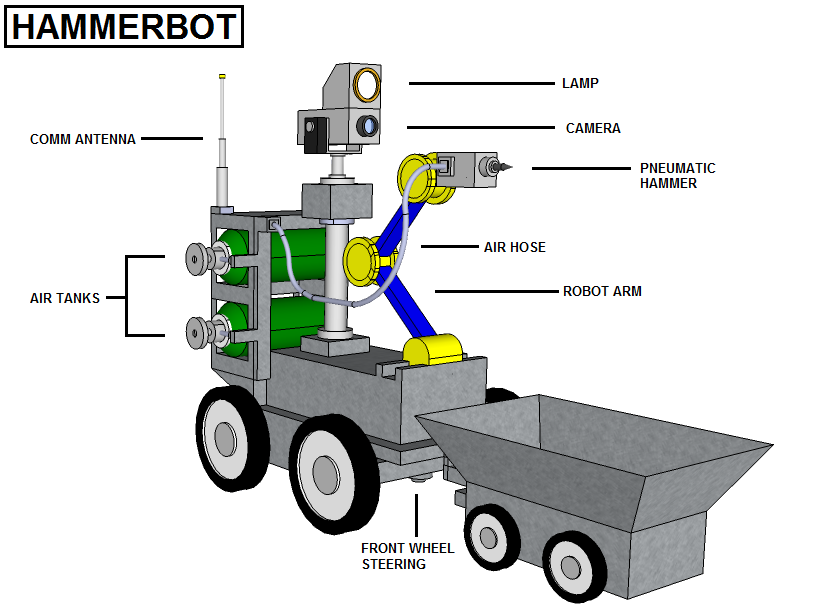

Robotic mining equipment is another application of robotics in the mining industry. These machines can be remotely controlled or operate autonomously, and can perform a variety of mining tasks, such as drilling, blasting, and excavating.

For example, Sandvik, a Swedish engineering company, has developed a range of robotic mining equipment, including remote-controlled drill rigs and loaders. These machines can operate in hazardous environments, such as underground mines, and can perform tasks more quickly and efficiently than human operators.

Inspection and Maintenance Robots

Inspection and maintenance robots are another application of robotics in the mining industry. These robots can inspect equipment and infrastructure for damage and wear and tear, reducing the need for human inspection and increasing safety.

For example, ABB, a Swiss-Swedish multinational corporation, has developed inspection robots for mining operations. These robots can crawl along pipes and tunnels to inspect them for damage and wear and tear, reducing the need for human inspection and improving safety.

Challenges and Limitations of Robotics in Mining

Despite the potential benefits of robotics in the mining industry, there are still challenges and limitations that need to be addressed.

One of the challenges is the cost of implementing robotics in mining operations. The initial investment can be significant, and there may also be additional costs for training and maintenance.

Another challenge is the need for specialized expertise in robotics and AI. Mining companies may need to hire experts in these fields or partner with companies that specialize in robotics and AI.

Conclusion

Robotics is revolutionizing the mining industry, making it safer, more efficient, and more cost-effective. Autonomous mining vehicles, robotic mining equipment, inspection and maintenance robots, and AI systems are just a few examples of how robotics is being used in mining operations. While there are still challenges and limitations to overcome, the potential benefits of robotics in the mining industry are significant. As the technology continues to evolve, we can expect to see even more innovative applications of robotics in mining, improving the safety and efficiency of this essential industry.

You must be logged in to post a comment Login