TECHNOLOGY

How a Cobot Collaborates with Humans for Maximum Yield

Automating collaboration is crucial to improving safety, productivity, and efficiency in the industrial world.

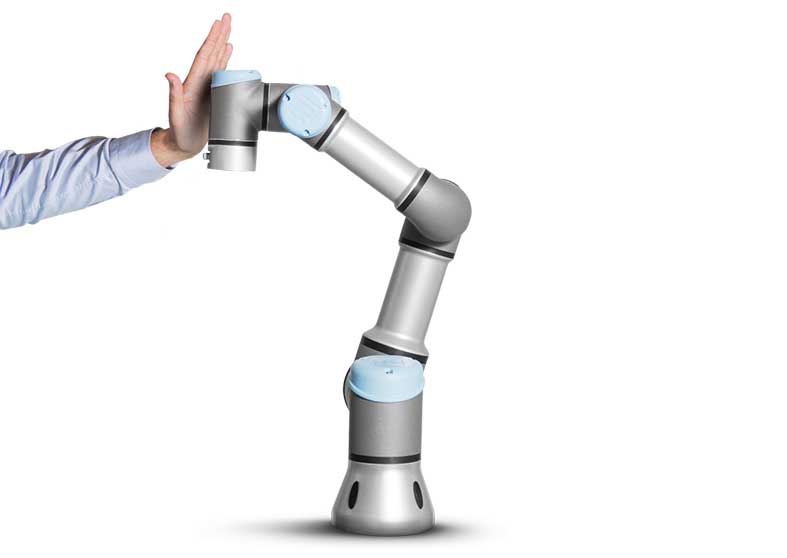

A cobot offers the solution as it can safely work alongside people on the factory floor, making it ideal for companies looking to automate processes and preserve their workforce. As such, they have some safety features that ensure they can operate safely in the workplace. In addition, they come with sensors that help them detect and avoid obstacles in their environment.

A cobot, a collaborative robot, works alongside humans and takes over dull, dangerous, and repetitive jobs. A cobot is an excellent solution that makes companies work faster and more accurately without replacing human workers. They need training and programming for each task to know what and how to do a specific job. They need an environment that allows them to move freely without hitting objects or people.

Features of a Cobot

Collaborative robots use force-sensing technology to detect a person nearby, allowing them to stop moving or reverse if something gets in their way. These sensors make them safer than traditional automation systems because they come without safety mechanisms like cages, safety guards, or barriers. Cobots operate within a safety envelope, monitored by sensors that detect the presence of people. The cobot will stop moving if someone gets close or touches its sides or top. Cobots can detect falling objects in their safety zone and prevent accidentally crushing them while performing the assigned task. The cobot has manipulators with arms of multiple joints that allow them to move objects around safely while avoiding contact with humans and other things in their proximity.

Collaborative Benefits of Cobot

Collaborative robots work with humans on the same line, performing different tasks as part of an integrated system or assembly line. They work side by side with humans and do not require a dedicated operator because of their ability to detect obstacles and avoid them when performing their tasks. Collaborative robotics technology combines the benefits of human operators with the advantages of robot automation. This technology has applications in many sectors, including education, manufacturing, and healthcare.

Safe to Work with Humans

A cobot works close to humans, and you can deploy it in various applications. They are easy to use and do not require any programming knowledge. For example, a cobot in an assembly line follows a specific path at speed safe for humans. Collaborative robots have built-in safety features to protect operators and enable them to avoid obstacles and prevent injuries arising out of human error.

Easy Integration into Existing Processes

Companies can purchase more than one unit and deploy them throughout the production line at various stages where they are needed most. They can perform tasks such as picking up objects or passing tools between people on opposite sides of a machine. Cobots help in more complex functions like loading parts onto an assembly line or inspecting products after production.

Fast Production

The benefits of a collaborative robot are many, but the most significant is the speed at which you can get your product to the market. Once an order has arrived, a collaborative robot will begin working on it immediately, and you will not have to wait for weeks or months before your order is ready.

Cost Savings

Collaborative robots are relatively inexpensive compared to traditional industrial robots. As a result, businesses don’t have to invest as much money upfront when purchasing them. And because they’re safe enough for humans to interact with, there’s no need for expensive safety equipment like cages or guards.

Easy Programming

Collaborative robots are easily programmed and used because they don’t require extensive knowledge of operating complex machinery, unlike traditional industrial robots. In addition, many models come with touchscreen interfaces that allow those users without experience with automation systems to learn how they work quickly. Cobots can adapt to various environments, which means they can apply in multiple applications. They’re also easy to teach so that people with little to no experience with robotics can use it.

Highly Flexible

Collaborative robots can handle a wide range of tasks and can adapt to different environments without requiring any additional components or hardware. This feature enables multiple settings and applications, from manufacturing facilities to warehouses and hospitals. In addition, you don’t need extensive training or experience with robotics to use collaborative robots effectively. Their design allows for easy programming through simple hand gestures or voice commands, so you don’t need any previous knowledge about how industrial machinery works or how it should be programmed and operated.

Helpful Across Industries

Cobots excel in different industries. Collaborative robots can perform tasks in manufacturing and distribution, healthcare, food and beverage manufacturing, and more. They are an excellent option for companies looking for flexible automation solutions that will help them increase productivity while keeping costs low.

Automotive manufacturers constantly strive to innovate and improve their performance to stay ahead of their competitors. Using collaborative robots in automotive assembly lines can help automate the manufacturing process and reduce the time taken to assemble a car.

The use of collaborative robots in education is growing exponentially as more and more schools adopt the technology. Collaborative robots best apply in situations where human safety is paramount, and students can benefit from increased levels of engagement.

Assembly

Cobots are excellent for assembly work because they can handle delicate parts without damaging them or risking worker injuries. You can make them follow precise instructions for assembling complex objects like airplanes or cars without making mistakes that could cause damage or delays if done by humans.

Reducing Waste

One of the main challenges faced by manufacturers is scrap due to human error during assembly lines or other processes. Collaborative robots can consistently carry out repetitive tasks without making mistakes or wasting materials. Collaborative robots present accuracy and consistency, making them perfect for painting or welding tasks.

Wrapping Up

If you want your cobot to help your company become more efficient and productive, you must ensure it carries the right tools. For example, your cobot must have arms that can reach above its head or plenty of torque in its joints to lift heavy objects easily without damaging itself or others.

Source link

You must be logged in to post a comment Login